Rolling Along

Preventative Maintenance: Minimize Labor & Parts, Maximize Revenue

When the height of the summer season is under way, the utilization of your fleets will be at their peak. It is natural for your mechanics to handle repairs when product is down, but less intuitive to stay ahead of preventive maintenance.

In your Maintenance Manual (located within your Franchise Manual) you will see that the first category in each product section is General Maintenance. This section covers key preventative maintenance areas that, when preformed regularly, will reduce wear, prevent product failure, and lessen the amount of time your mechanic spends maintaining your fleet. We recommend having your maintenance teams review these pages in their Maintenance Manual as a training refresher.

In your Maintenance Manual (located within your Franchise Manual) you will see that the first category in each product section is General Maintenance. This section covers key preventative maintenance areas that, when preformed regularly, will reduce wear, prevent product failure, and lessen the amount of time your mechanic spends maintaining your fleet. We recommend having your maintenance teams review these pages in their Maintenance Manual as a training refresher.

Particularly during the peak season, mechanics tend to gravitate towards only fixing out of service product and we often hear that they believe they don’t have time to do the preventative maintenance required. This could not be further from the truth and our response in this situation is to advise the mechanic that their time is actually better spent doing the preventative maintenance on a regular basis as this will result in less product in need of repair, reducing the number of hours needed to maintain the fleet.

Routine preventative maintenance throughout the season minimizes total maintenance labor hours. As an example, assuring tires are properly aired up takes much less time than replacing a rear Surrey flat tire that has a pinch flat. Proper chain adjustment is less time consuming and more desirable than forcing a customer to walk a cycle back to the site because the chain was thrown off. Review your fleet – if you see a Surrey with two bald front tires, it is a sure sign the front wheels need alignment and a sure sign that you are replacing front tires twice as frequently as necessary. When a pedal that hasn’t been kept tight hits an object, there is a good chance it will tear out the threads in the crank arm. Keeping headsets and coaster brake hubs adjusted extends their life and reduces failures. Issues such as these increase overall labor expenditures, as well as total parts spend. Preventative maintenance has a direct impact on these expenses, and attention to this area will bolster the bottom line.

Routine preventative maintenance throughout the season minimizes total maintenance labor hours. As an example, assuring tires are properly aired up takes much less time than replacing a rear Surrey flat tire that has a pinch flat. Proper chain adjustment is less time consuming and more desirable than forcing a customer to walk a cycle back to the site because the chain was thrown off. Review your fleet – if you see a Surrey with two bald front tires, it is a sure sign the front wheels need alignment and a sure sign that you are replacing front tires twice as frequently as necessary. When a pedal that hasn’t been kept tight hits an object, there is a good chance it will tear out the threads in the crank arm. Keeping headsets and coaster brake hubs adjusted extends their life and reduces failures. Issues such as these increase overall labor expenditures, as well as total parts spend. Preventative maintenance has a direct impact on these expenses, and attention to this area will bolster the bottom line.

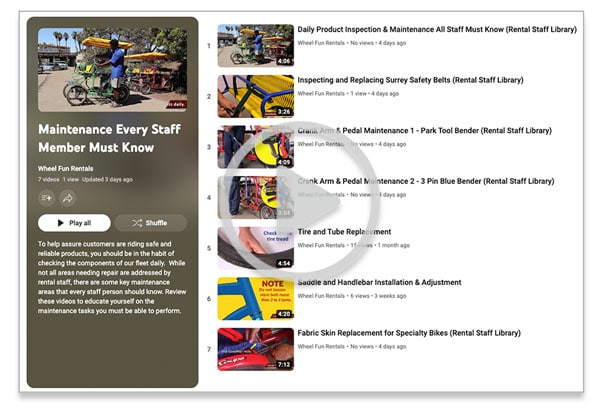

As a reminder, Wheel Fun Rentals has put together a series of Fleet Maintenance Videos, with many of them in the preventative maintenance category. If your mechanics have not seen them, we would recommend they take the time to review them all. Click the button below to view the Full WFR Maintenance Video Library.

While your mechanic’s primary function is to maintain the fleet in tip-top shape, not all of that responsibility falls only to them. Rental Staff should also be trained to assist in daily preventative maintenance (and some non-mechanic staff should be trained to adjust Surrey brakes, adjust chains and headsets, etc.). We have compiled all of the tasks that Rental Staff should be able to perform and we have gathered those training videos into the “Maintenance ALL STAFF Must Know” training series (this is a subset of the Maintenance Training Videos).

While your mechanic’s primary function is to maintain the fleet in tip-top shape, not all of that responsibility falls only to them. Rental Staff should also be trained to assist in daily preventative maintenance (and some non-mechanic staff should be trained to adjust Surrey brakes, adjust chains and headsets, etc.). We have compiled all of the tasks that Rental Staff should be able to perform and we have gathered those training videos into the “Maintenance ALL STAFF Must Know” training series (this is a subset of the Maintenance Training Videos).

These videos cover daily and weekly tasks that all staff should be trained in to ensure that any product down time is minimized and you have 100% of your revenue-generating fleet in motion at all times. Click the Image to the right or the button below to review the new series for all of your rental staff.